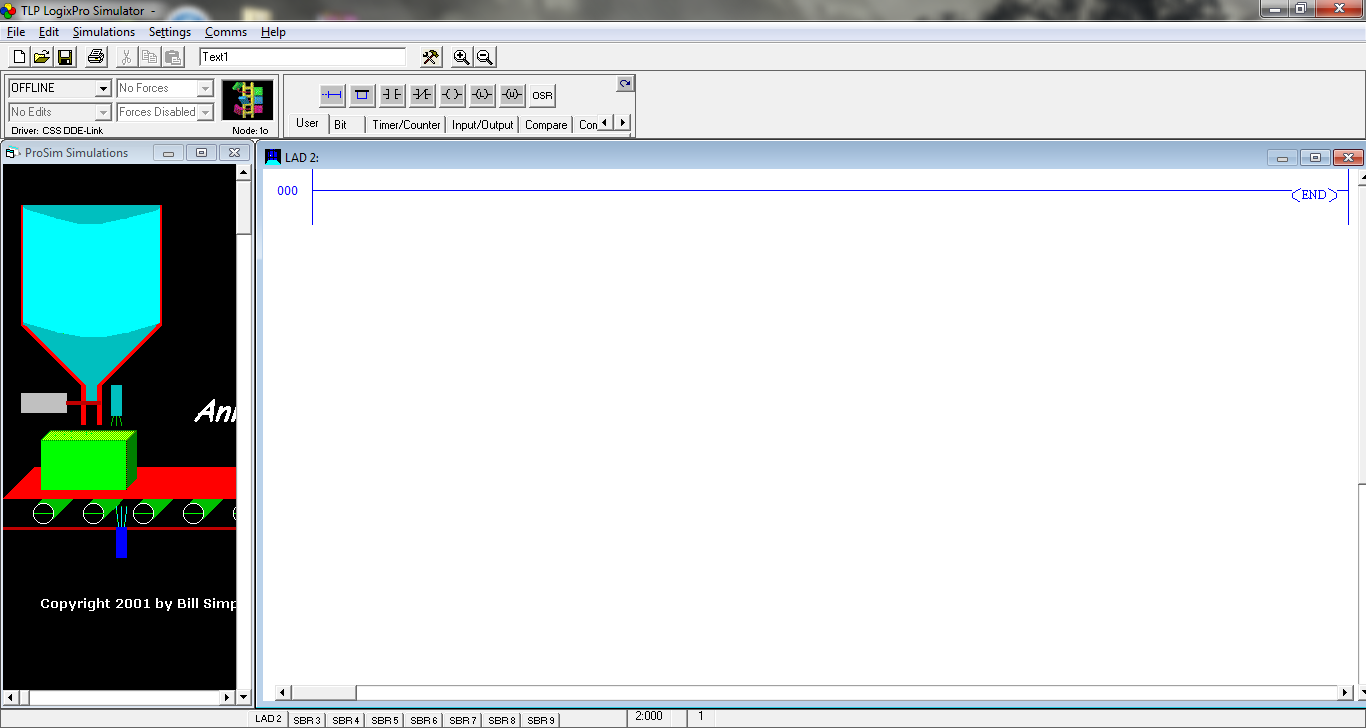

of working for the mixer then the timer will de-energize the mixer as shown in rung No.I see a few things that I would use to reduce your homework score.ġ. (003) the mixer will initialize a timer (T4:0) to calculate 30 Sec. (001), as you can see there is an NC contact for the mixer on the HEATER coil so the heater can not be turned on when the mixer is ON. Notice that there is an interlock between the heater and the mixer represented in Fig.(1), the THERMOSTAT NO contact will be closed and it will de-energize the heater operation and it will energize the MIXER to start mixing the fluid as shown in rung No. And now is the role of the THERMOSTAT when the temperature of the fluid reaches the setpoint temperature that is represented in Fig.So, for the second rung (001) as you can see when the HIGH_LEVEL switch will indicate the level it will de-energize the filling pump “PUMP-(1)” and also it will latch the HEATER to increase the fluid temperature. Regarding the application AFD, PUMP-(1) should be turned ON till it fills the tank (HIGH_LEVEL energized).(3) for the first rung “000” whenever we press the START button it will energize the Latching coil for the output that is responsible to operate PUMP-(1). Now by starting with the first condition which is by pressing START, PUMP-(1) should turn on.Īs we can see in Fig.“Before we start to discuss our solution, it is very important to give it a try by yourself for just 15 min.” Now and after we have discussed and summarized the batching process operation the next step is to clarify the Input and Output signal list as followed: F unction Address START I:1/0 STOP I:1/1 HIGH-LEVEL I:1/4 LOW-LEVEL I:1/3 PUMP (1) Q:2/1 PUMP (2) Q:2/3 HEATER Q:2/4 MIXER Q:2/0 THERMOSTAT I:1/2 Translating the batching process conditions into Ladder instructionsĪlways remember that programming is not as hard as you imagine all you need is to start step by step and whenever you feel that your PLC code becomes to be complicated and not organized, be sure that you are on the wrong path.

0 kommentar(er)

0 kommentar(er)